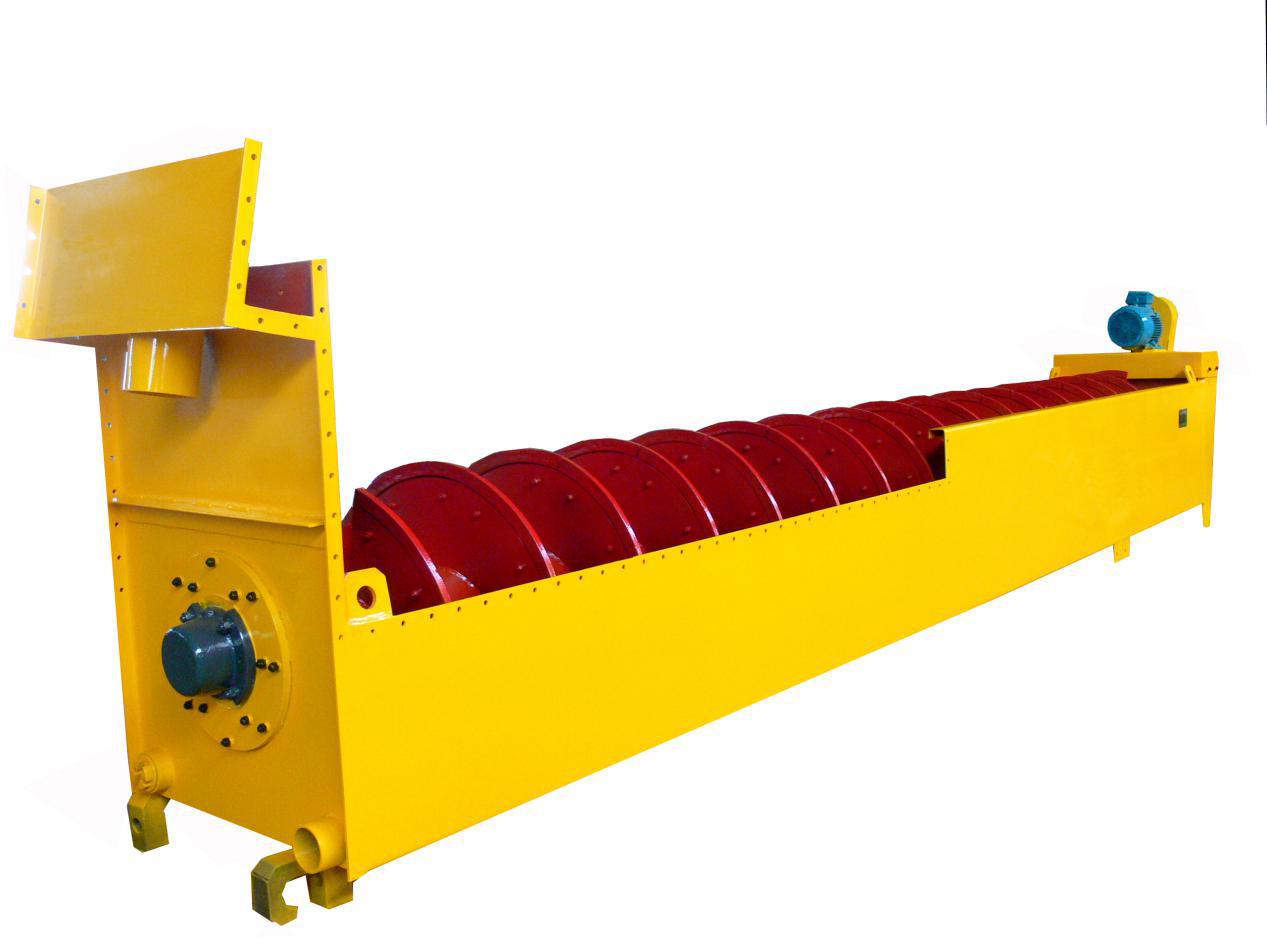

Screw type Sand Washer

LSX series sand washer is our screw type sand washer, it can wash, classify and de-watering various sands.

|

Input size: |

0-10mm |

| Capacity: | 0-350tph |

| Processing material: | Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so on |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU