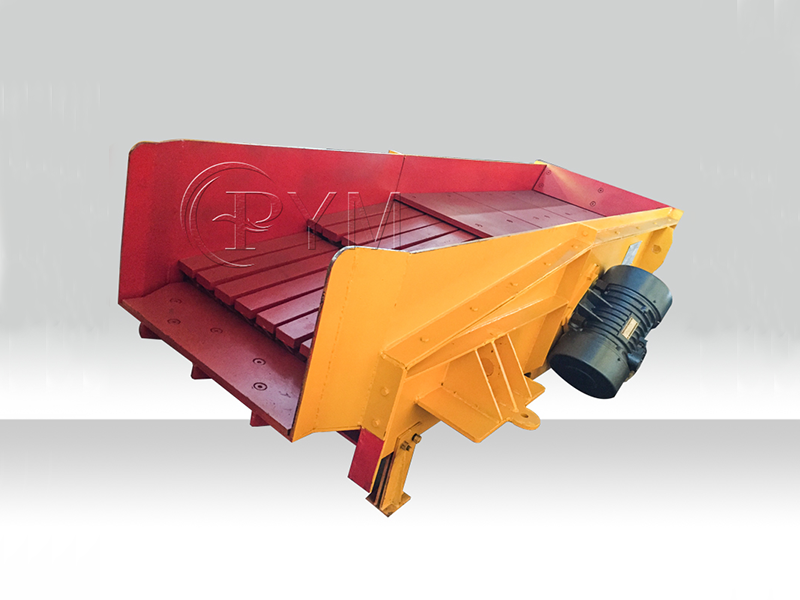

Vibrating Feeder

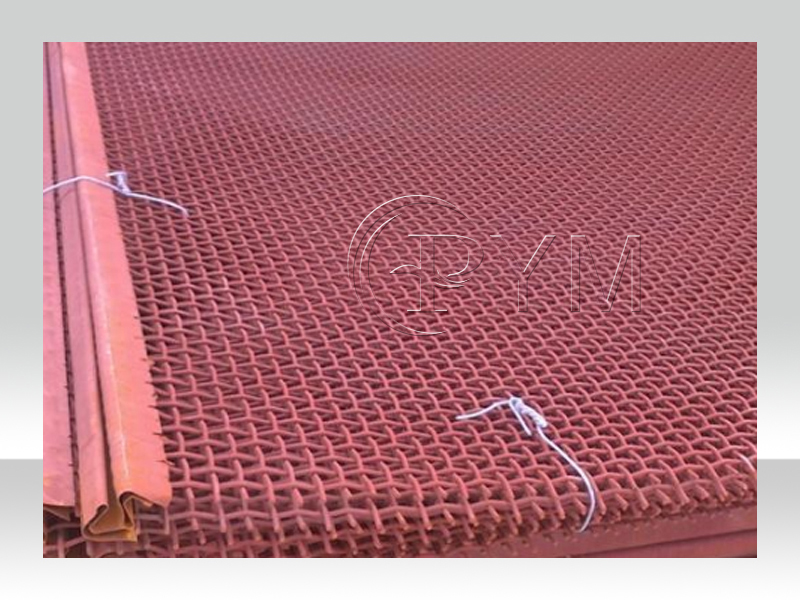

Vibrating Feeders are generally applied before jaw crusher for feeding material continuously and uniformly, the grizzly bars can separate the sand and soil primarily.

| Input size: | 0-800mm |

| Capacity: | 40-600tph |

| Material: | Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so on |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU