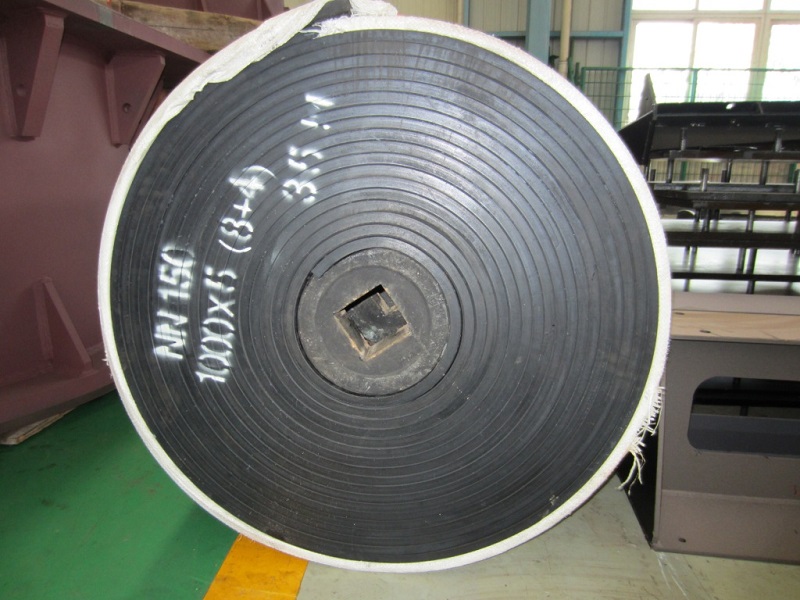

Rubber belt with high wear resistance

We designed and customized many different type rubber belt according to customer demands, because our cooperated partner is the professional rubber belt factory with more than 30 years.

| Belt width: | 400mm -- 1400mm |

| Material uses | polyester ,whole-core,cotton, nylon, steel wires etc |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU