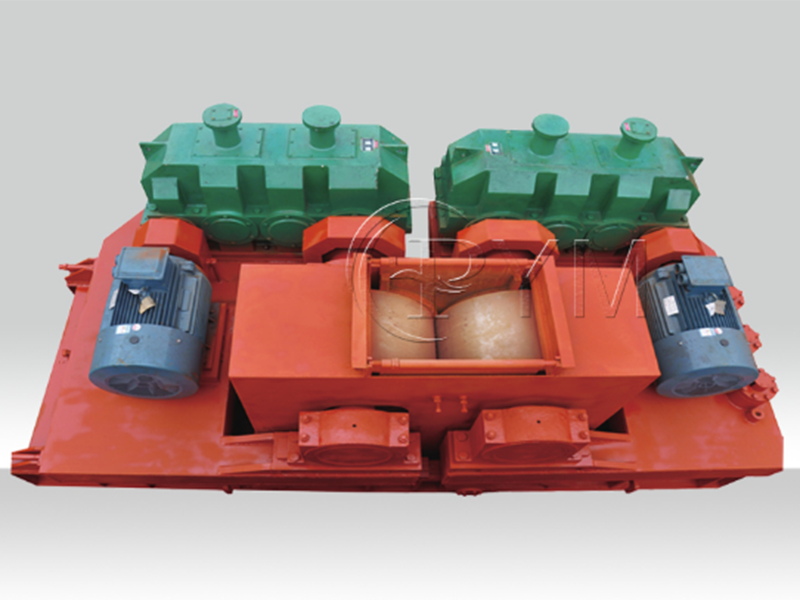

Mobile Crusher Plant

Mobile crusher plant is very easy to transport from site to site, which is quite suitable for road construction.

| Input size: | 0-800mm |

| Capacity: | 50-350tph |

| Material: | Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore etc. |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU