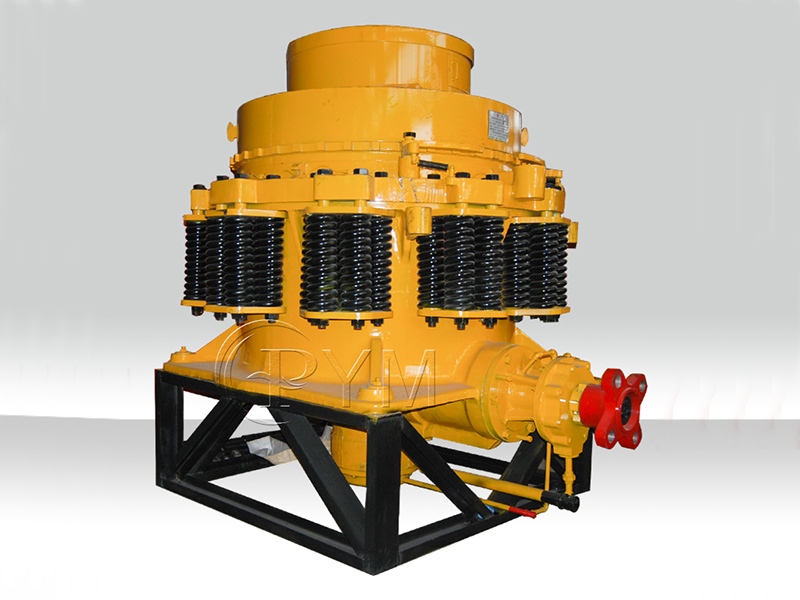

Multi-cylinder hydraulic cone crusher

The multi-cylinder hydraulic Cone Crusher is another major research of Shanghai PYM with hydraulic control device, it is more comprehensive and sensitive than compound cone crusher. The additional hydraulic insurance and hydraulic locking device make the machine more convenient and faster.

| Input size: | 0-350mm |

| Capacity: | 0-1000tph |

| Material: | Granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc. |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU