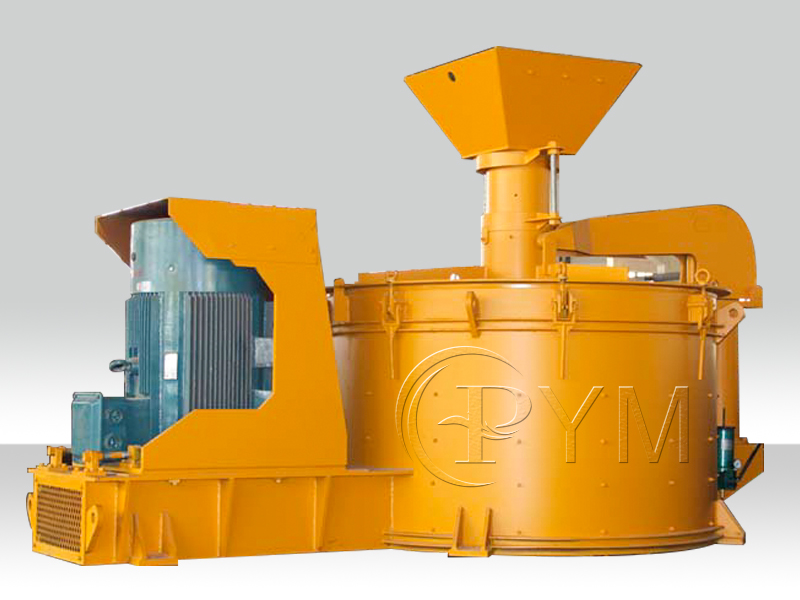

Hammer Crusher

PYM's hammer crusher can be used as primary crusher and secondary crusher before of its big feeding opening. It can save the investment cost largely when used for primary crushing.

| Input size: | 0-1000mm |

| Capacity: | 10-500tph |

| Output size: | 0-100mm |

| Material: | Limestone, dolomite, sandstone with compression strength less than 150Mpa |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU