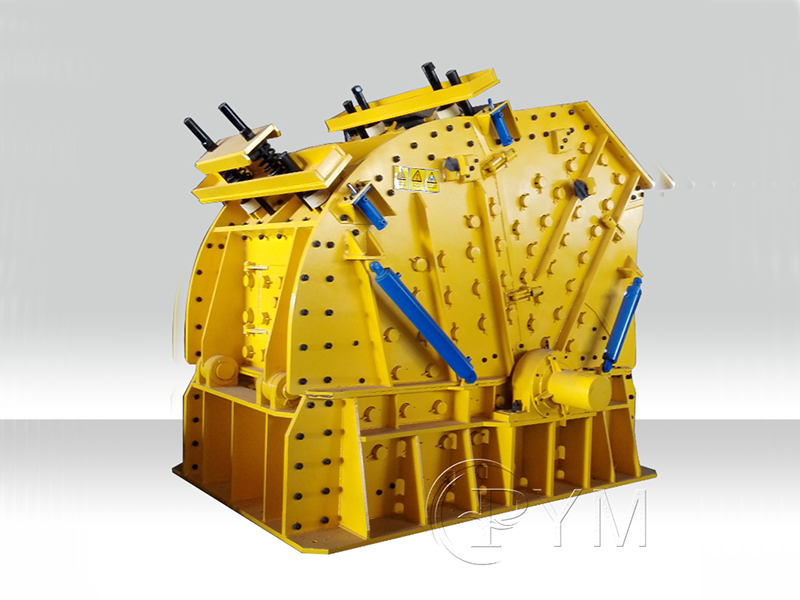

Heavy-duty Apron Feeder

Heavy-duty apron feeder can be used for horizontal or inclined direction from the warehouse to the crusher, conveyor or other work or loose mechanical transport all kinds of bulk-like material.

| Feeding size | 0-1800mm |

| Capacity: | 50-900tph |

| Material: |

Coal, Ferrous metal ore, non-ferrous metal ore, river pebble, limestone, dolomite, granite, rhyolite, diabase, basalt etc. |

| Application: |

Widely used in building materials, metallurgy, mining and other industries. |

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR SW

SW AR

AR RU

RU